For today's post, I thought I would shed a little light on that cut setting that causes confusion "Thickness". Many of you know your cutter very well and know what works, however, if I asked you what thickness means could you describe it to someone else. This is the topic I am asked about most. What is the thickness setting?

10 blade settings at 10 speeds at 33 thicknesses so there are 3,300 settings to set your cutter too when using the standard blade (not counting the double cut or track enhancing). It is amazing the choice we have at our fingertips.

Presets are your friend.

Quite often I hear "I don't use the presets." said in a voice that sounds like its a bad thing to do. I wish I had all the presets when I got my craft robo back in the day. Presets are there to give you a start point, a suggestion of what the cut settings could be and while these may give you a perfectly decent cut, sometimes you need to change them to give you that crisp finish.

So you have picked out the media you want to cut and chosen an appropriate match for it in the cut settings window, after doing a test cut the results are not quite what you would like them to be. The cut hasn't quite gone through the media. Stop!!!! Do not dial up that blade! If you have set your blade to the correct setting and you increase the blade length, you run the risk of breaking the tip off your blade or cutting through your mat.

|

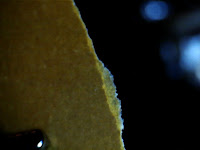

| The correct blade setting for silhouette chipboard. |

More often than not the thickness settings can fix this problem.

All card is not created equal, if you were to look at a card from different manufacturers under a microscope they will look quite different.

Although two cardstocks may have the same weight, the way they were made can be very different each being made up of different size particles, different binder holding it all together, using different dye or bleach, it may also be coated. The photos on the left show in order from top to bottom brown paper, silhouette chipboard, vellum and white cardstock, note the different fibers in all four. It is these differences that affect the Thickness settings that we need to choose.

Thickness refers to the density and more. If you imagine your in a swimming pool of water you can move along with some resistance you don't have to work too hard. This will be our number 3 setting now imagine someone comes along and puts custard powder in the water it becomes thicker and harder to move through. As more custard powder is added it get harder and harder to move through. Increased effort is required to move through thicker materials so thicker media requires a higher thickness setting so it will push harder while cutting, pushing harder does not mean deeper. The custard does not have to be deep to slow you down just thick. this is why when you want to cut a heavyweight vinyl, the thickness setting needs to be increased although we would consider this a thin media as it has no depth, it can require quite a force to cut. When increasing your thickness settings give thought to your speed. if you are cutting with a high thickness setting you have an increased risk of damaging your blade as it takes a little longer for the blade to rotate in its housing. A slower speed will allow the blade to turn and change direction more effectively. For media not in the presets choose which closest matches your media and use a serious of test cuts to determine the best settings, write down your results on the packaging in a notebook or save them to your computer. Test cut test cut and test cut getting the settings right will save you a lot of cardstock.

So next time your thinking of which settings to use consider, custard.

PRODUCTS USED:

|  |  |  |  |

Wow this is such a helpful article! I thought thickness referred to the depth of the material, not the density. It all make sense now. Thank you so much.

ReplyDeleteGlad it helped Heather, your not alone in you thoughts.

ReplyDeleteSilhouette really need to change the wording to pressure. Thank you for making it so clear.

ReplyDeleteSomething to consider Suky! happy crafting X

ReplyDelete