Hi gang, Nadine here with a tutorial on how to etch metal using salt water (electro) etching.

In my last post, I shared a technique that I learned on a recent jewellery making holiday for etching dichroic glass to make pretty fused glass pendants. Whilst on the same course, I also learnt how to salt water etch copper. This is a technique that I've been wanting to try for quite a while so was glad to really get to really experiment and get to grips with it. Karen at La Vidalerie has very generously agreed that I can share my learnings with all you fabulous folks.

I etched the tribal cat design to make a Victorian style Christmas tree decoration in France and the folk art tree to make a keyring for our lovely Lisa here at Silhouette UK once I got home.

How Does Salt Water Etching Work

Metal can be etched in many different ways, but the basic principle is the same. A 'resist' is applied to protect parts of the metal. The metal is then added to a solution which eats away the parts of the metal which are not protected. This is exactly the same idea used in my fused glass pendant from last week - my vinyl penguin was the resist and the etching cream was an acid that ate way the sparkly dichroic top layer.Traditionally, acids or corrosives such as ferric chloride are used to eat away the exposed metal, but in this technique we only use salt water. Acid is not needed, as we can generate the 'bite' by passing the current from regular household D size batteries through the salt water!

People like salt-water etching as it's cheap and effective, does not require chemicals and allows for easy disposal. Whilst the list looks long, the items are easily available from the supermarket / eBay. I tallied up the total cost to set up and it came to under £10. This technique works on copper, but also other metals such as stainless steel and brass. I'll definitely be experimenting with these metals too, so watch out for tutorials on these coming soon!

What you need:

- Water, ideally de-ionised

- Pure salt

- Plastic or glass beaker

- 2 size D batteries

- Battery holder

- Cables with crocodile clips

- Scrap piece of copper

- Copper piece to be etched

- Copper wire

- Vinyl

Step One: Dissolve salt in water

Dissolve the salt in the water until the solution is fully saturated - heating in a pan can speed the dissolving process up.Make sure to use pure salt, as table salt normally has anti-caking additives or small amounts of other chemicals such as iodine. Kosher or rock salt is perfect. De-ionised water is the pure stuff used in steam irons and I picked a big 2.5 litre bottle for a pound at the car section of the supermarket.

Top tip

Whilst this seems like the perfect job for the shed or garage, if the liquid is warmer the etching will be faster.

Step Two: Prep Copper

Prep the surface of your copper to ensure there is no grease or fingerprints that could obstruct the etching process. The easiest way to do this is to lightly buff with a fine wet and dry sand paper.Step Three: Cut vinyl and apply to copper

Cut your vinyl, weed and apply to your piece using transfer tape. Remember to cover the back of your piece with vinyl to protect it also. That anything that is protected with vinyl will be left unetched and will be raised and is often polished, whereas anything exposed will be etched and sunken, often darkened.Top tip

It's sometimes hard to envisage which how the final piece will look. I use Silhouette Studio to help me - I colour the vinyl pale brown to represent the shiny raised surface and the weeded section dark brown to represent the etched darker surface as shown below.

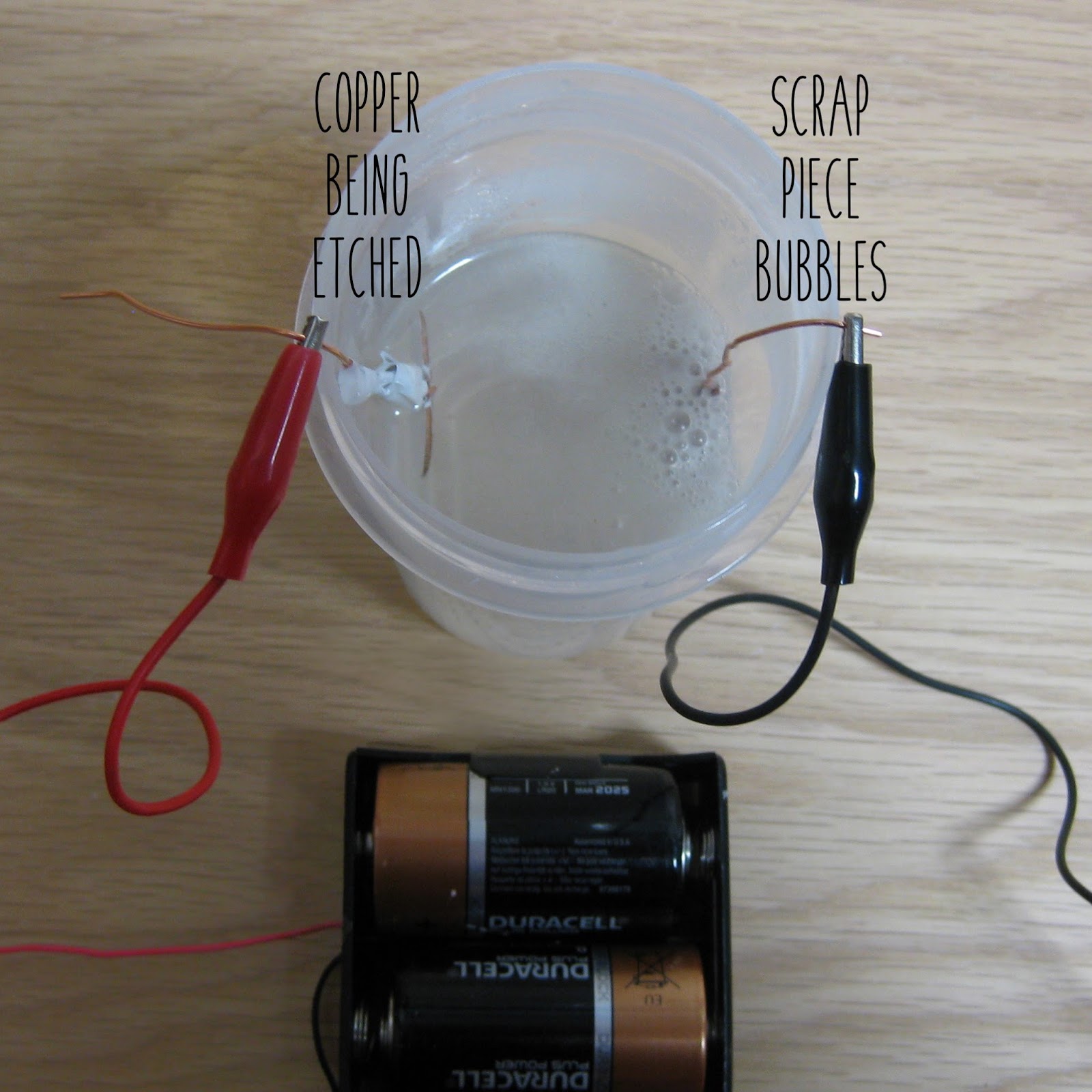

Step Four: Attach to Batteries

Attach your piece to the positive (red) cable. You can attach the piece directly, or via some copper wire. If your piece doesn't have a hole, you can tape the wire to the back. The key is to make sure you have good contact so that the current flows through the piece well.Attach your scrap piece of copper to the negative (black) cable. This piece will be attracting the copper from your piece and can be used over and over again.

Place both pieces in the salt-water solution, facing each other.

Top tip

Remember the bubbles will appear on the scrap piece of metal not your piece. The best way to remember the correct set up is the motto Karen taught me - "I'm positive I want to etch"

Step Five: Etch

Your speed of etch will depend on the surface area being etching, the amount of current being used and other factors such as the temperature of your solution and how many times it has been reused. Mine etched for 20 minutes, and I checked the progress a couple of times - here's a quick snap I took after 7 minutes:Step Six: Finish piece

Disconnect the battery cables and give your piece a wee clean. Remove the vinyl resist. Copper looks nice oxidised (darkened) with raised parts highlighted and polished to a high lustre. To do this apply some Liver of Sulphur or Plantinol - see how here and then polish up the surface with super fine wet and dry paper or use my favourite ultra polishing pads.Step Seven: Disposal

The copper will sink down and you can reuse the solution many times over. When you are finally finished, allow the water to evaporate, leaving just the copper and salt sludge. Contact your council for your local metal waste disposal.FINISHED PRODUCT

DESIGNS USED:

|

|

PRODUCTS USED:

|

|

|

|

Wow! That is amazing Nadine - extreme crafting! Thanks for giving us such a fantastic idea and tutorial x

ReplyDeleteNadine you are so talented. Thank you for sharing this with us. Can I please ask the proportion of salt to water? Many thanks. x

ReplyDeleteHi Wendi, thank you for the kind comments, but the talent belongs my teacher Karen! I didn't measure the salt just kept adding until it was fully saturated - I used about half a box of the Maldon salt in a large beaker of water. I think people mention a 5:1 ratio on other sites. It doesn't matter if there is a little too much salt at the bottom.

ReplyDeleteIn awe, these are stunning.

ReplyDeleteI think I have just about everything to hand already, so if I do this, I will send you a photo. Amazing technique!

ReplyDelete